MCP 7200 Stationary Concrete Pump

MCP 7200

• Superior metallurgy : Best in the market,

Hard chrome plated delivery cylinders, Carbide wear plate & High wear resistant S valve as standard offering,

• Simple hydraulic system with standard valve blocks.

• Single pump circuit with sequential control.

• Automated greasing system.

• Low lying agitator with two high torque motors boosts the suction efficiency.

• Hopper with 600 litre capacity, designed without any dead angles. to improve the concrete feeding to the suction line.

• S valve with smooth reduction over longer distance (200x180) ensures very low pressure loss.

• Simple control panel with wired remote as a standard.

• Safety : warning lamps - low engine oil pressure, V-belt , battery charging.

• Bent plate type chassis with high section modulus.

• Heavy duty tail wheel.

MCP 7200 Stationary Concrete Pump Specification

| S.No | Parameters | Values | |

|---|---|---|---|

| 1 | Technical Identification Number | 2025 | |

| 2 | Differential Cylinder Drive | Rod Side | Piston Side |

| 3 | Maximum Concrete Pressure | 60 bar | 90 bar |

| 4 | Maximum theoritical output | 72 Cu.m | 48 Cu.m |

| 5 | Maximum number of strokes | 28 | 18 |

| 6 | Maximum horizontal placing distance | 350 m | 600 m |

| 7 | Maximum Vertical placing distance | 90 m | 130 m |

| 8 | Area Ratio (Hydraulic / Concrete) | 0.2 | 0.3 |

| 9 | Delivery cylinder diameter x stroke | 200 * 1400 | |

| 10 | Delivery cylinder volume(litre) | 44 * 2 | |

| 11 | Drive Cylinder | 110 / 63 | |

| 12 | Engine | KOEL HA 694 | |

| 13 | Drive power | 81 KW | |

| 14 | Hydraulic circuit | Open Circuit | |

| 15 | Hydraulic Oil Volume | 300 Litres | |

| 16 | Volume of Hopper | 600 Litres | |

| 17 | Type of Valve | S Valve ( 8" ) | |

| 18 | Axle | Spring | |

| 19 | Auxiliary System ( Options ) | Compressor / Water Pump | |

| 20 | Weight | 4500 Kg | |

| 21 | Hopper Feeding Height | 1.3 m |

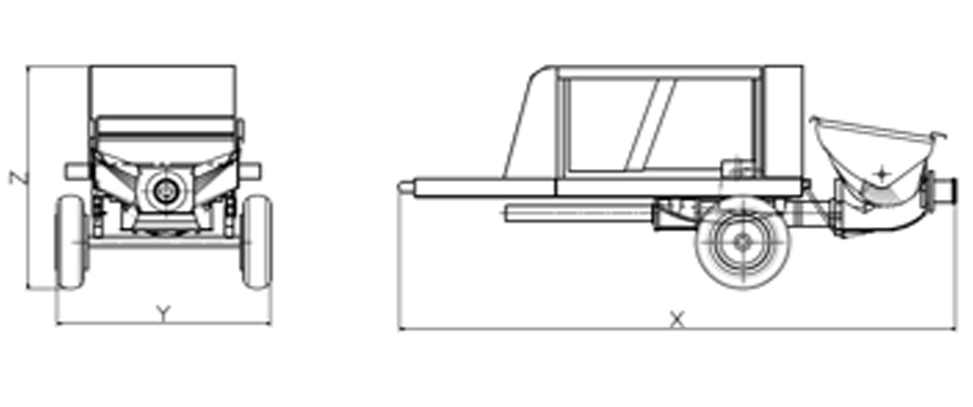

DIMENSIONS OF MCP 7200

DIMENSIONS (X x Y x Z) : 6100x2090x2250.

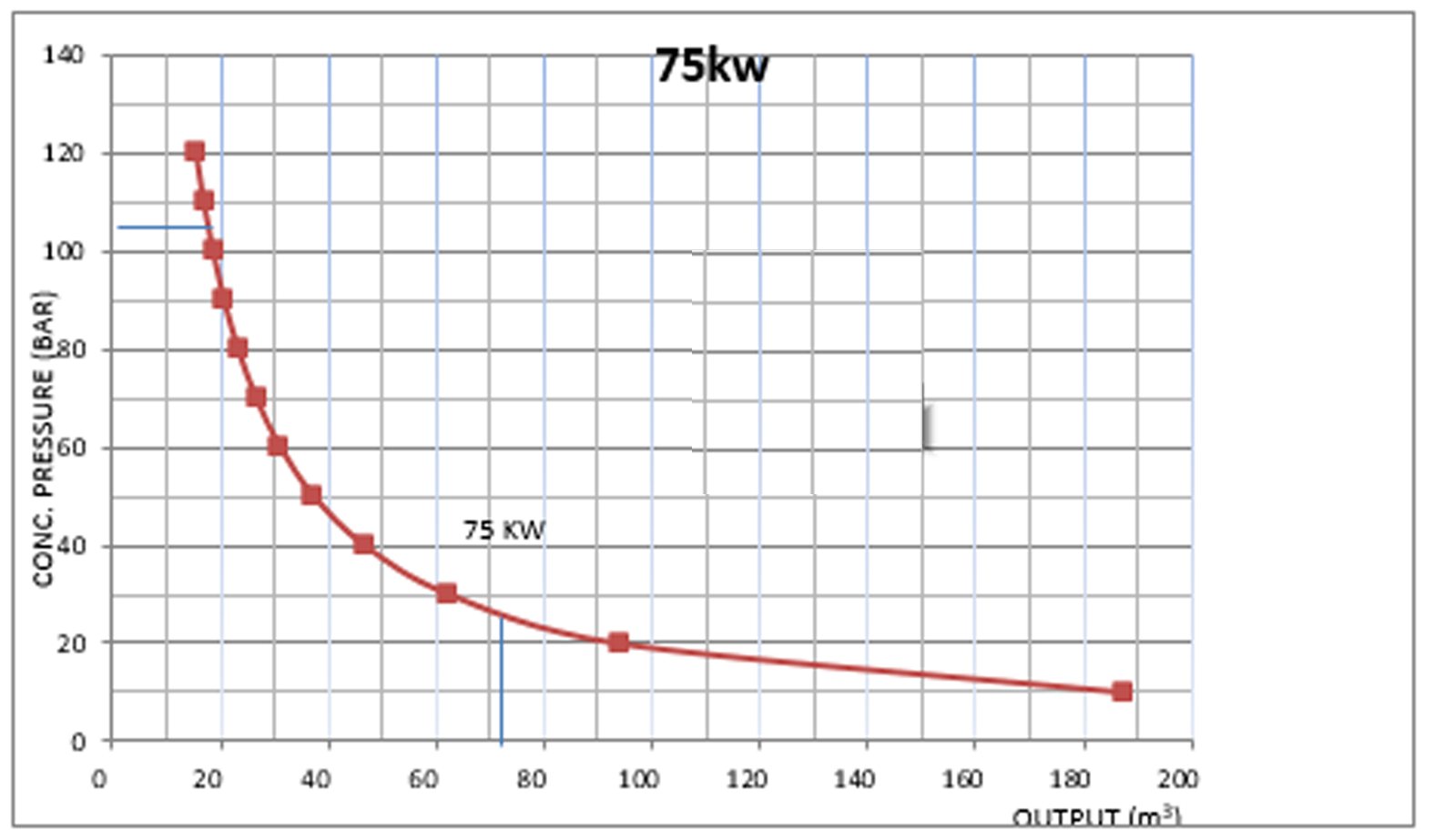

OUTPUT GRAPH